A workshop is equally as secure as you create it. As you’re liable for the safety of the employees, an individual has to be certain about appropriate workshop security. A superb house workshop demands that you take good care of safety measures. You will have to keep all of the steps in your mind while you take up a project with risks entailed. Whenever you are likely to be in your workshop, never imbibe alcohol. You have to prevent working at the workshop when you are stressed. You should only work when you feel comfortable and in charge of the body and your mind.

All stores and garage workshops must be under the control of a controller, who is responsible for ensuring they’ve been maintained and utilized in a wholesome and safe way. Just those official to do so can enter or work in stores or workshops or and must fulfill with their supervisor while in this zone’s requirements.

A tidy workplace does not interfere with work operations and provides it easier to identify and avoid threats. Excellent housekeeping is vital to workshop security management, and enough time must consist of things like clearing afterward. This pertains to both different and familiar locations.

Before it is possible to use equipment and machines or attempt work that’s practical in a workshop, then you must know basic safety rules. These rules may help keep you and others safe while working at the workshop.

1. Use Safety Gears

Always wear safety equipment while working in the workshop. Safety gloves, shoes, glasses, and helmets are all required for doing carpentry, equipment fitting, plumbing, or welding. Some people usually do not utilize welding eyeglasses while dealing with welding functions. This may cause temporary or permanent blindness, which means you need to put on a welding mask or glass while performing welding work because welding sparks may destroy the tissues of the eye.

2. Read the Safety Guidelines Properly

Always sure that security guidelines are assessed while working together with automobiles. Pull the hand brake, Choke the wheels and fender covers that are suitable. Always jack other vehicles or the cars onto a solid surface or utilize spreading blocks for the load.

3. Spatial Arrangements

- The Tiniest distance among Installations, machines, loads of materials, and belongings should be at a minimum of 600 mm (approx. 2 ft).

- You must spot pathways by the suggested yellow lines. That might assist in the separation of Pathways from other nominated work zones.

- The Pathways contact straight to the exit must be broader than 1100 mm (3.6 ft).

- Pathways perhaps not be greasy due to attire or moistness also.

- The Pathways must be effectively upheld and should be free from hurdles.

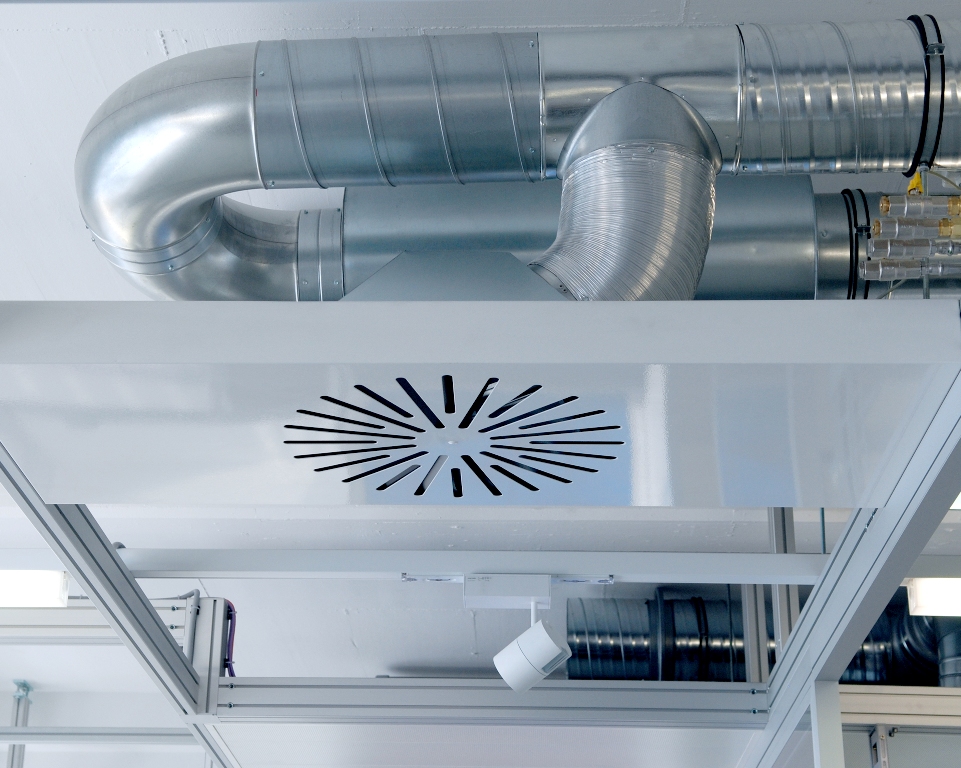

4. Ventilation

I) Dilution

Dilution airing systems will provide at least three fresh air exchanges per hour and at least 7.1 liters per minute per individual.

II) Local Exhausts

All processes, including the release of corrosive or flammable gases, poisonous, dust, vapors, mists, or fumes, will be supplied with an exhaust construction capable of taking pollutants at the origin. Design necessities are described from the Industrial Ventilation Guide – A manual of training, American Conference of Governmental Industrial Hygienists.

The opening from local exhausts should be situated at the roof level and the slightest 25 ft — distance from the near air opening.

5. Safe storage

Gear, gaseous, or solid chemicals, liquid, and fittings should be saved. Corrosion or damage of containers may lead to product leakage, which pollutes surfaces beneath, creates slide dangers, and might respond to sort a fume or fire threat.

The physical procedure of storing things trips, slip-ups, has risks via managing and falls out of improperly stored items and objects dropping from a height.

6. Malfunctioning Precautions

Malfunctioning machines may occur at any time. It could arise through the machine’s screw tightening or replacing the engine. Irrespective of the sort of break, not ever attempt to work on it while the machine’s switch is on, and it is currently running. Components have a selection of mistakes, apart from their design, make, or technology. Even if the break down is more routine and requires just tightening, it is almost always a fantastic idea to turn your machine off and then do the fixing. Shocks are capable of damaging human cells because of this workshop machines have very high-power evaluation.

7. Fire Precautions

The flame would be the most bizarre, although workshops tend to mishaps generally. Injury drills are an integral part of workshops, and they help employees prevent them, and if there is only with a ready staff, it might be the best approach to reduce the damage that occurred.

Conclusion

These are a few guidelines and the rules which will help keep a check up on hazards and mishaps. Most prominently, safety is a concern. Improving work efficiency with minimal drawbacks is what workshop managers would love to reach. In the event, work principles and security recommendations are followed and observed strictly. It’s always critical because the problem never comes declared to stay prepared for a medical or accidental crisis, and that is what workshop security rules do.

Author Bio:

Lucerin Saldana

With her passion for making interior and exterior attractive in workshop buildings of all sorts, Lucerin is a trusted author, bringing up new ideas in creating unique styled steel buildings and workshops. She has studied about different ‘Construction and Non-construction materials’ and worked with some leading metal garages manufacturers and suppliers.